Product Design

Product Life Extension

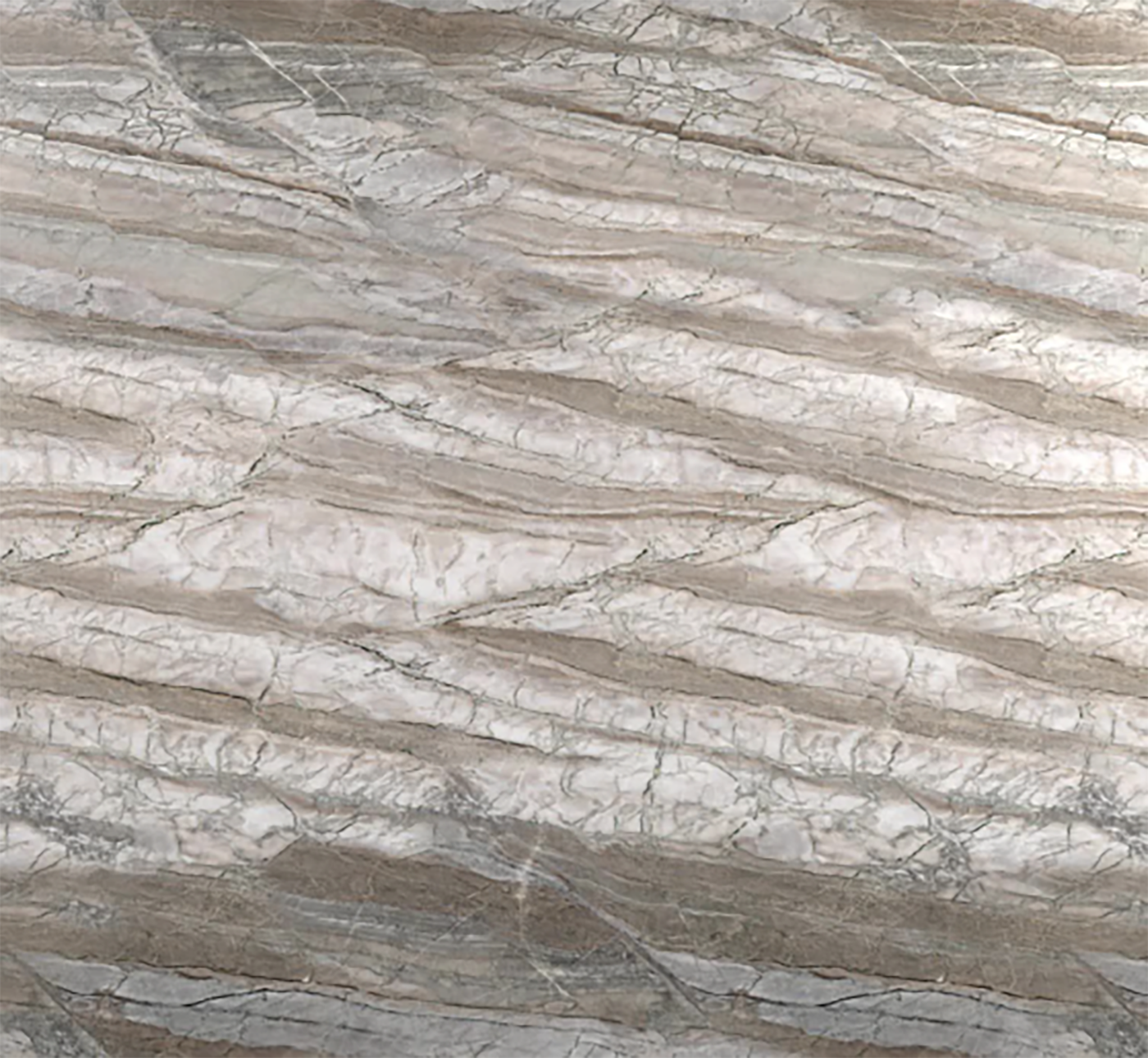

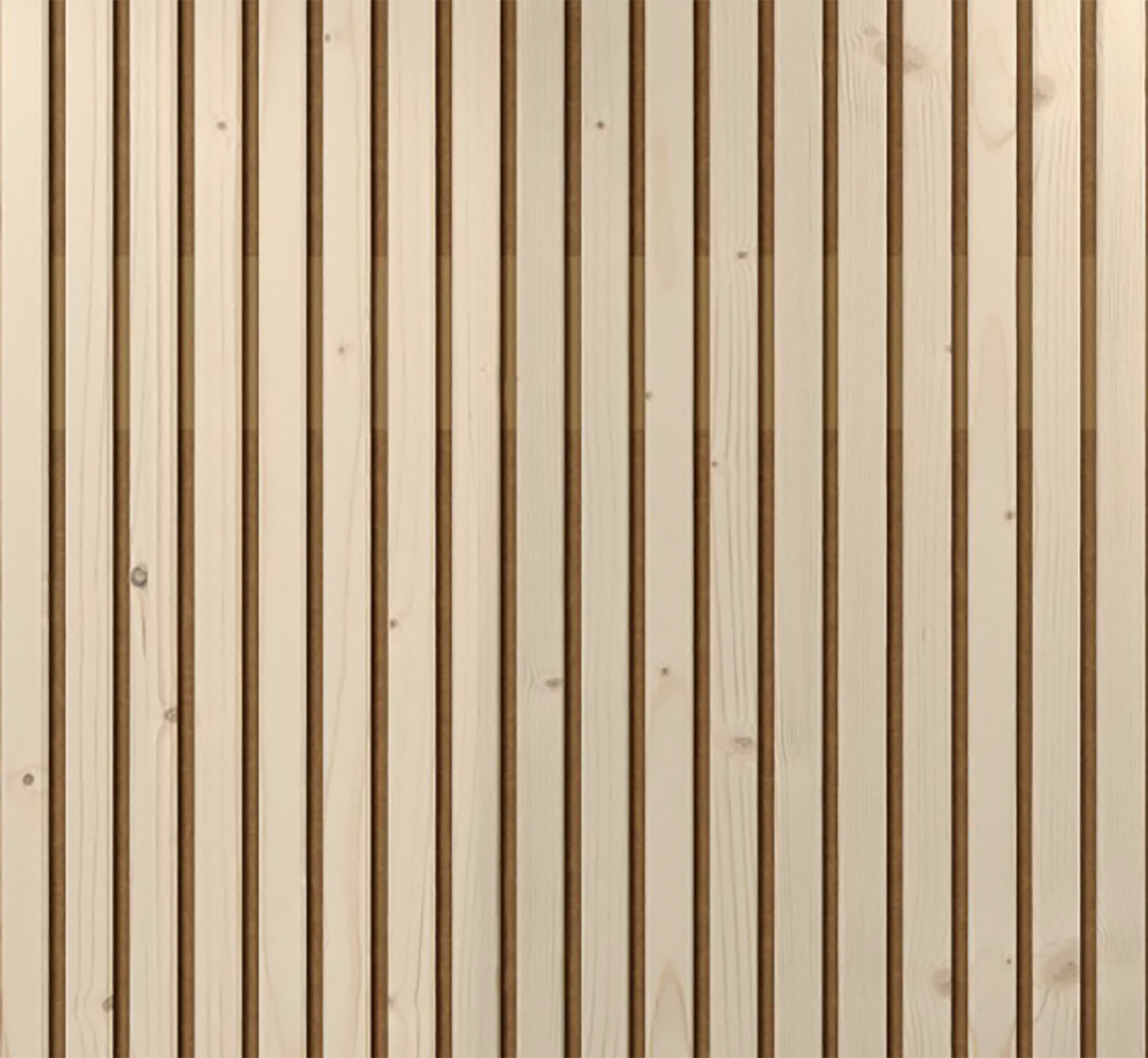

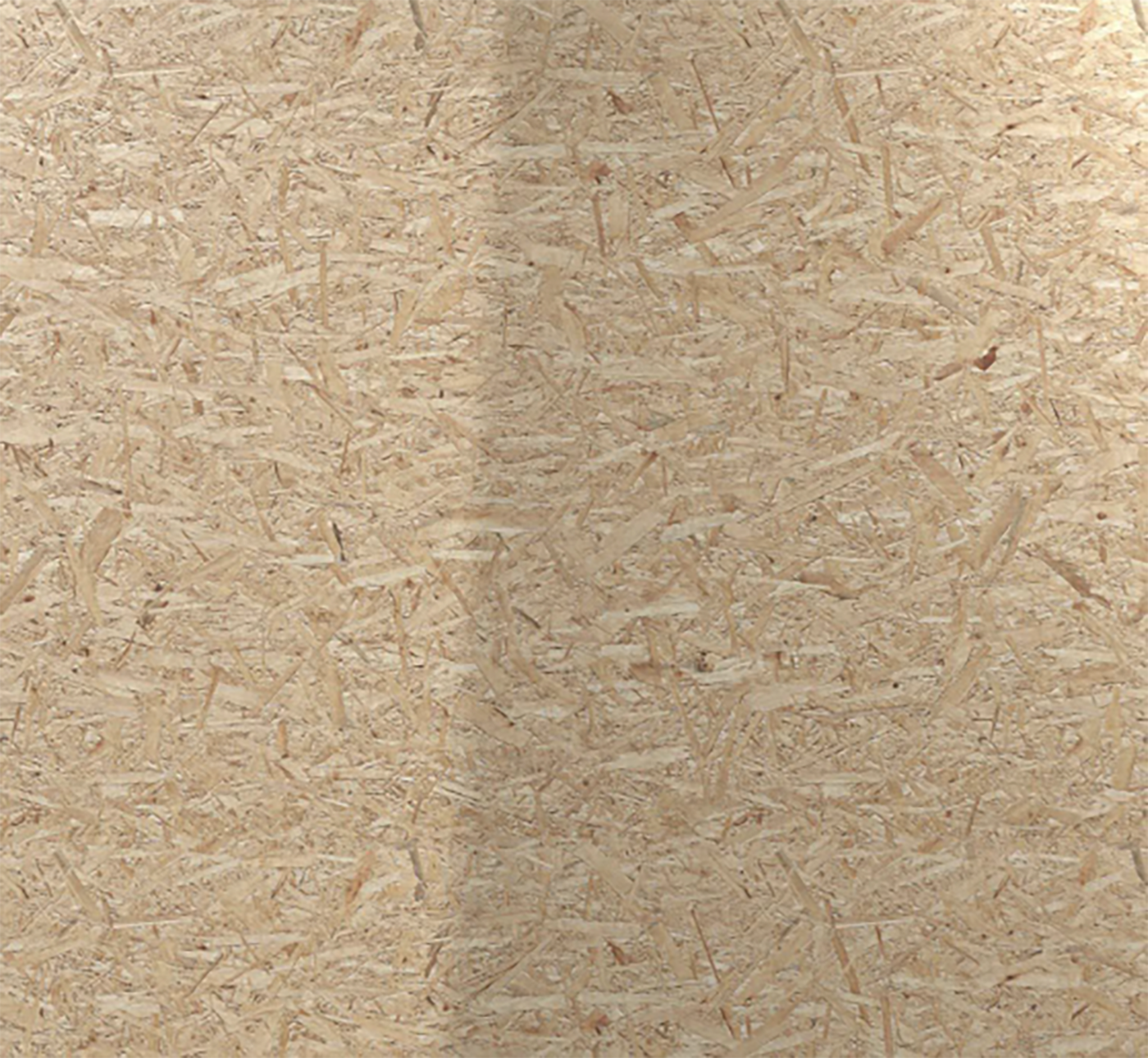

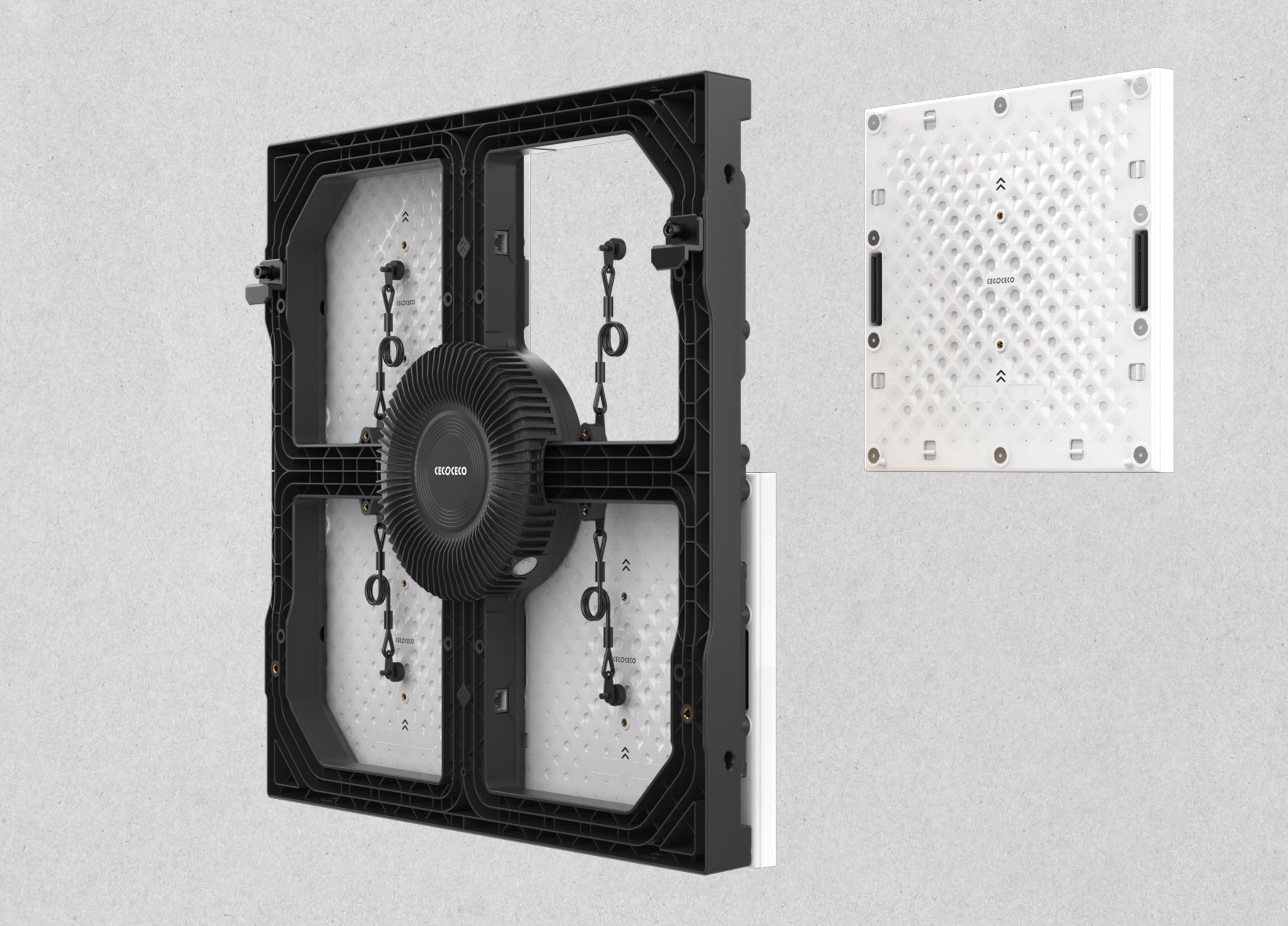

Recycling electronic components: Users can only change the covers and keep the electronic components of ArtMorph when they want to change the style. Lifetime of electricity part can be used at least 10 years.

Prolong product lifespan and minimize resource waste: Internal and third-party specific tests are conducted to make sure that our products are resistant to moisture, dust, impact, oxidation, static electricity, blue light, and other factors.

Energy Saving

Lightweight design: Lightweight products reduce transportation loss, manpower loss, and electricity consumption.

Auto temperature-based color adjustment: Conductive devices are developed to detect environmental changes and automatically adjust product parameters, which also helps to reduce energy consumption.

Reduce aging hours: The aging time of LED panels is adjusted from 72 hours to 60 hours, which is shortened by 12 hours.

Materials and Production

Package: Change from plastic to cartons. All cartons will be recycled.

High-Quality LED: We use the best quality LEDs for our products with higher luminous efficiency and longer service life, resulting in lower energy consumption and less waste.

Renewable Material: Covers and Back Shells are made from polycarbonate which is renewable.

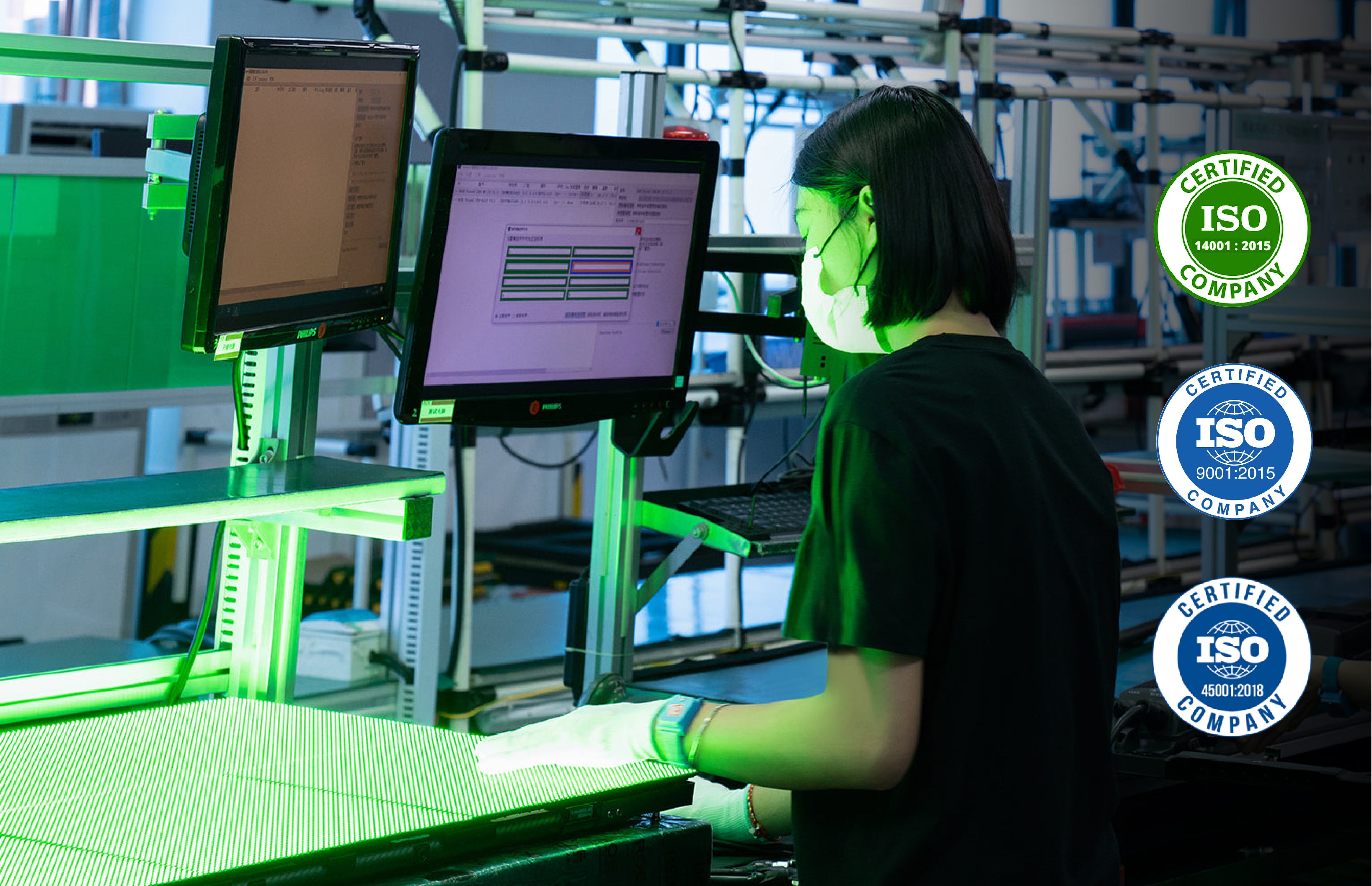

Full implementation of the lead-free production process to meet ROHS requirements: Conduct a thorough review of all production processes and materials, identifying those that contain hazardous substances. Ensure that the substances and chemicals used during PCB manufacturing and assembly do not include harmful elements in the form of impurities. Insist on using lead-free solder and material, training staff to increase their skill. CECOCECO will act if non-compliance is found. (We have ISO 9001:2015 - Quality Management Systems, ISO 14001:2015 - Environmental Management Systems, ISO 45001:2018 - Occupational health and safety management systems.)

Chemical Inspection: Daily inspection of chemical use, weekly inspection of explosion-proof cabinets, monthly comprehensive inspection, and report on the solid waste platform.

Product Transportation

Reusable Transfer Boxes

Using reusable transfer boxes to transfer raw materials from suppliers to CECOCECO.

Procurement from Local Companies

The transport distance of 90% suppliers are between 30km to 80km. Reduce carbon emissions during transportation.

What are we going to do in the future?

Use Clean Energy: Replace the fuel forklifts with electric forklifts.

Exploring Alteratives to PC: Based on current architectural requirements such as fire-proofing and durability, CECOCECO cannot produce this product without PC at the moment. However, we are continuously seeking new materials to replace it.

Covers Recycling Plan: CECOCECO is developing a comprehensive plan for cover recycling.